Disperse ink used on which print heads?

- Kyocera KJ4B-QA normal speed 600DPI,

- Kyocera KJ4B-YH high speed 600 DPI,

- Kyocera KJ4B-1200-high resolution 1200dpi,

- Kyocera KJ4B-0300- double color head 300 DPI,

- Epson heads,

- Other heads.

The SUPERINKS disperse ink used on printer brands as:

- Dilli, DGI, etc.

- Atexco, Hanglory, Homer, Efi, Liyu, JHF, Flora, etc.

- Xkeda, Fedar, kycolor, Grando, Human, etc.

The features:

- High color saturation, wide gamut, brilliant colors,

- No ink flying, No ink bleeding, sharp pictures,

- While colors transfer from paper to textile, high transfer rate on colors,

- The quality and color of different batches are unchanged,

- Low vapor emission, environment-friendly,

- Nanotechnology, superfluidity, low sedimentation rate prevents nozzle clogging,

- Good resistance to dry/wet rubbing, high light fastness,

- If the sealed bag packing, the expiry date can be 24 months,

- Competitive prices.

This SUPERINKS disperse ink has the following colors:

- Cyan, Magenta, Yellow, Black,

- Light Cyan, Light Magenta,

- Gray,

- Red,

- Blue,

- clean liquid.

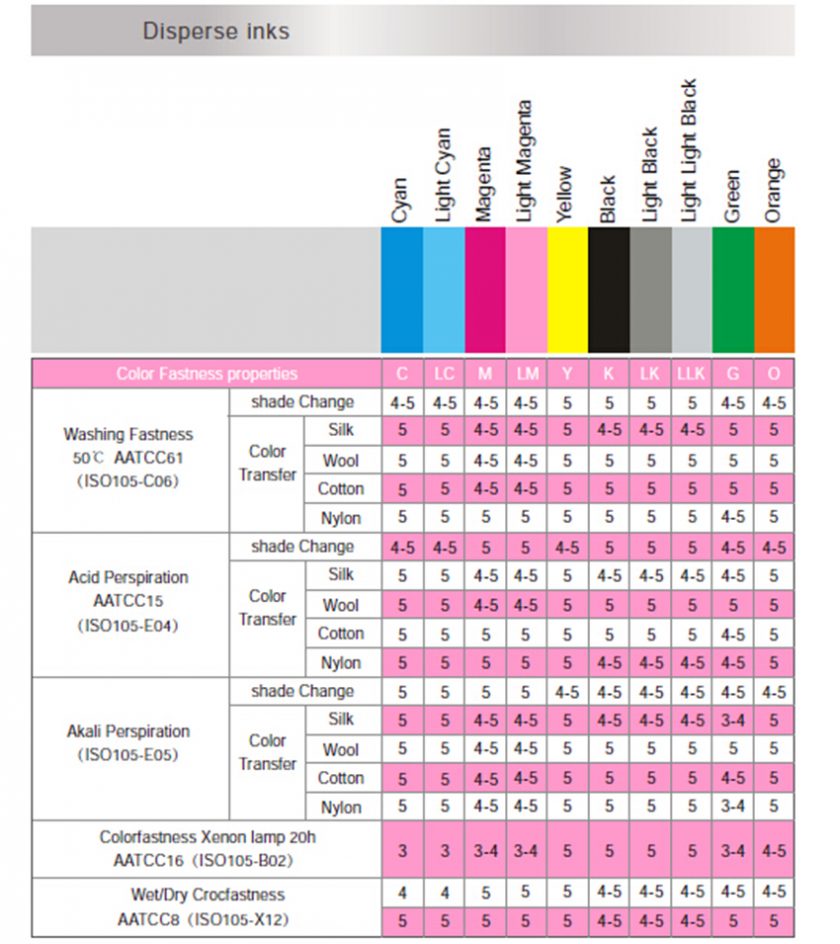

The color fastness of those colors are:

The main features of disperse dye ink digital textile printing:

- High density, very bright color,

- No ink flying, No ink bleeding, sharp pictures,

- The quality and color of different batches are unchanged,

- Has good color fade resistance,

- No harm to the body,

- These dispersed dye inks produce vibrant colors, reproduce a wide gamut of colors, and have water resistance, light-fastness, and rub-fastness because of dyestuff molecule bonding with the fibers.

Applicable materials:

- Polyester,

- Fabric with more than 80% chemical fiber.

What is the difference between sublimation ink and disperse ink?

Actually, from the ink technology, it is the same ink. But the working process of using is different. Sublimation ink mainly uses two methods, one is printing on heat transfer paper, then heat transfer to polyester, normally for clothes. Another is direct printing on sized polyester, normally for AD flags. Both without water wash, mean with less pollution. Disperse ink, usually working as the following process. Sizing, dry, printing, steam, wash, dry.

This SUPERINKS disperse dye ink working process:

- sizing,

- dry,

- printing,

- steam,

- wash,

- dry.

SUPERINKS’ available package for disperse ink fabric printing:

- Drum/Bottle pack in 25 KG,

- Drum/Bottle pack in 20 KG,

- Drum/Bottle pack in 5 KG,

- Drum/Bottle pack in 1 KG,

- A customized package is available.

Instructions:

- Operating temperature: 20-30℃, Operating humidity: 40-60%.

- Shake the ink well before putting it on the machine; It will be best if you can use it up within 1 week after opening.

- Before using our products for the first time, please empty the ink cartridges, ink circuits, and dampers. If possible, please clean the ink circuit system and replace it with a new damper.

- It’s very important to make an ICC profile to get brilliant colors, if need to make an ICC profile, contact us, we will help.

What’s the difference between DTF ink, DTG ink, and disperse ink?

All those 3 inks are mainly for cotton fabric. Each ink has a different process. Disperse ink can get the best color, and best resistance, but need a more complex process. More used for high-quality level printing.

DTG pigment ink printing for T-shirts is an old technology but has not had a big market share for years. DTF technology almost solved all problems that DTG has. It solved not a bright color, not good wash resistance. Though the hand feel of DTF is a little bit more, it can improve step by step.

T-shirt printing is a huge market, especially pure cotton, especially black pure cotton T-shirts (Before, no technology solved well how to print a soft and bright pure cotton black T-shirt).

Transport and storage conditions:

- Avoid direct light, and storage temperature at 15-30℃; after opening the seal of the package, please avoid dust and other sundries going into ink composition.

- The goods are identified as Non-dangerous goods in accordance with IMO, RID/ADR, IMDG, ICAO, IATA.

- MSDS available.

Which types of fabrics are suitable for which inks?

- Plant fiber: cotton, linen, etc.

Suitable for: DTF pigment ink printing, DTG ink printing, disperse ink printing. - Chemical fiber: Polyester etc.

Suitable for: Sublimation ink printing, disperse ink printing - Silk: Mulberry silk, tussah silk, rayon, synthetic filament, etc.

Suitable for: Disperse ink printing. - Animal hair fiber: Mink fur, wool, rabbit fur, camel fur, etc.

Suitable for: Disperse ink printing, Acid ink printing.

SUPERINKS factory introduce video:

Youtube: https://youtu.be/-M0yrUgOXLY