In 2018, to meet increasing demand and expand production capacity, SUPERINKS established a dedicated water-based ink manufacturing facility in Gaoyou, Jiangsu Province—Cobo RX Co., Ltd. Building on this foundation, until 2024, SUPERINKS has centralized its entire ink production operations in Gaoyou, creating a fully integrated campus that houses an R&D center, ink manufacturing lines, packaging facilities, warehouses, and administrative offices. This strategic consolidation streamlines operations enhances efficiency, and reinforces SUPERINKS’ commitment to delivering high-quality ink solutions under one cohesive roof.

1). 6S management system.

All our factory produce center management system is 6S (improve from 5S) management, which learns from a Japanese factory. And we keep our factory in 6S management every minute.

SUPERINKS produce center’s ink production has an “automatic feeding system”, automatic grinding equipment, automatic mixing equipment, and automatic filtering equipment. To make sure feeding precisely. And if the filter element needs to be replaced, the device will alarm.

The automatic machines save labor costs and avoid mistakes.

2). Incoming material quality control.

3). Produce and process quality control.

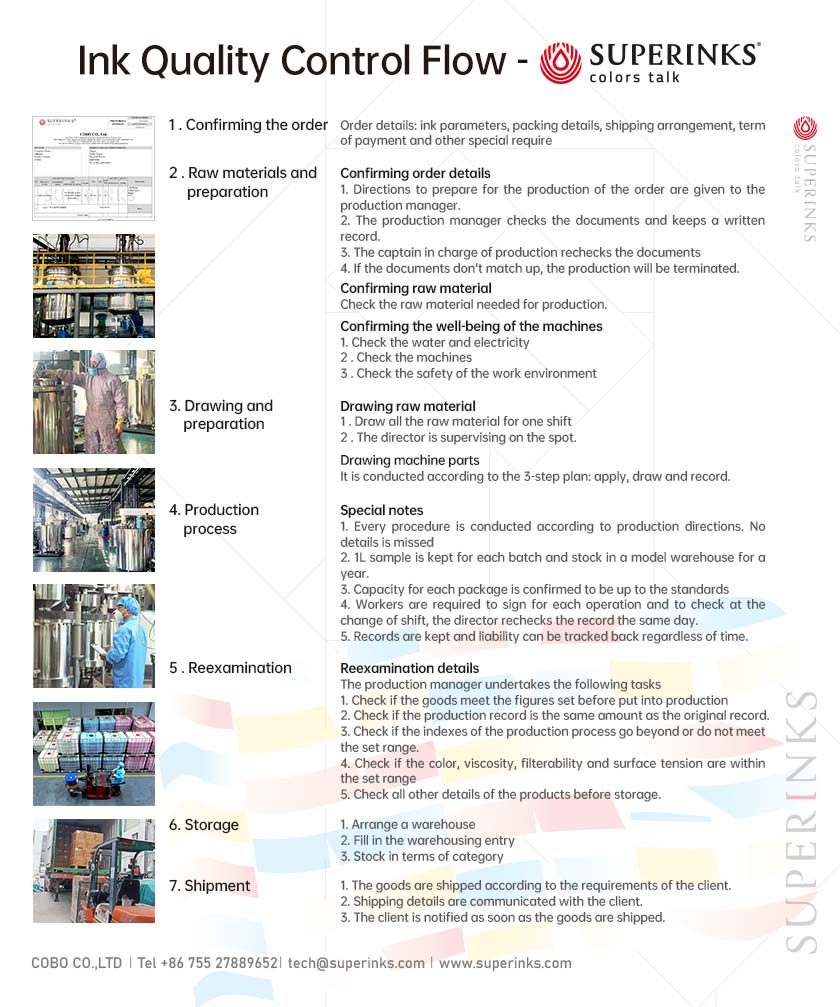

The ink quality control flows of SUPERINKS will be under strict principles, traceable for quality.

4). Ink bottle production in our production center.

We have our own mould for our ink load bottles and make them in our own factory. This makes sure that the quality of bottles, avoids leaking. And makes sure that the lead time of ink orders is under control.

5). Printing test inside the factory.

6). Outdoor durability test.

Some ink from the Chinese market has a short outdoor durability life, like 3 months, 6 months, or 10 months. Which affects the outdoor durability? How to extend? We have the full range of data for it.

SUPERINKS has 24 months more durability solvent ink and eco solvent ink.