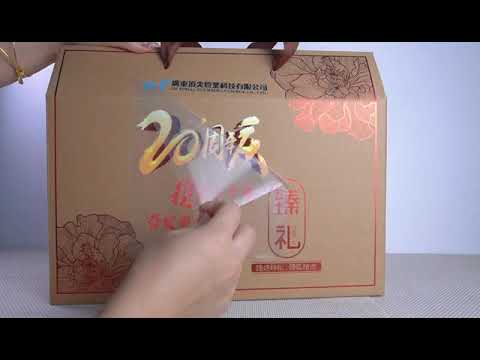

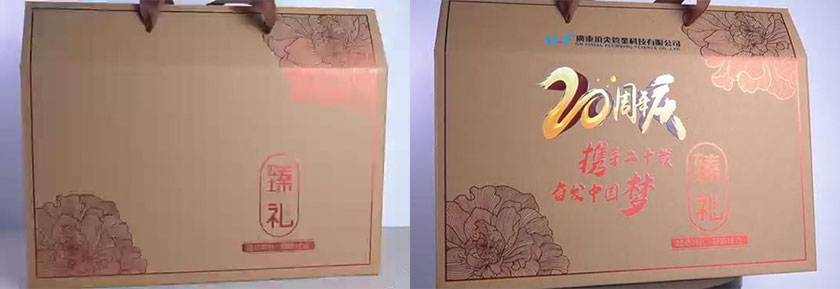

DTF UV printing is for hard substrates, like gift pictures.

(One). What is DTF UV ink?

There are 2 methods For DTF UV ink printing.

- Old method: AB film printing. The process is as follows:

- Take out A film, which with glue on the surface, and usually it is A4 or A3 size, can not in a roll.

- Peel down the surface of A film, expose the glue surface, and then layout the glue surface on the flatbed printer, firm the four corners to the printer flatbed.

- Print white colour, and then CMYK colourful pictures.

- Cover B film and laminate.

- Use cutter equipment (or cut with scissors by hand) along the edge of the picture.

- Take out a picture from A film, stick the product surface, and peel down B film.

- New method: improved method, print glue direct from the print head.

- Take out A film which with a layer of coating to absorb ink, without glue on.

- Print glue, and then white, and then CMYK for pictures, and then glossy. So, one printer with at least 4 heads.

- Roll up the printed film. Send to the customer, anytime he wants to use it, peel one picture from the film, and stick it on the surface of a product.

This glue direct printing DTF UV can do industrial printing, and the printer is very cheap. We can have good wishes for this. But the glue printing by head is still a big challenge and difficult to improve.

DTF UV printing only works on hard product surfaces. It is for small logo printing. Does not require any plate making, can do small quantity printing. Very fast printing, customer send job, wait half hour, then he can take the finished product away. This kind of printing job with very high-profit margin.

(Two). What’s the main difference if using DTF UV printing

- The printer should have at least 4 heads, one for glue, one for white, one for CMYK, and one for varnish.

- The film is used for DTF UV printing.

- The glue is special, should have good adhesion, and be friendly enough to printer head. Usually, glue is not friendly enough for the print head.

- CMYK and varnish are normal UV ink.

(Three). If you have more questions, you can message us.